Breaker insert processing examples

|

Before improvement

After improvement

|

|

What is PcBN?

Polycrystalline cubic boron nitride (PcBN), which was developed in 1972, is a mixture of crystal grains of carefully selected cubic boron nitride and a binder. It is artificially made in an ultra-high pressure/ultra-high temperature environment and does not exist in nature. It has hardness next to diamond. PcBN is an abrasion-resistant article with high hardness at high temperature, high wear resistance, high impact resistance, and high thermal conductivity.

Other than diamond, there are no substances that exceed these performances. When cutting ferrous materials by PCD, chemical reaction occurs and graphitization progresses. However, this is not the case with PcBN.

It has the advantage that almost no chemical reaction occurs even when it is used for iron, nickel, cobalt, etc. Furthermore, no oxidation occurs even at high temperature of 1,200 ℃.

Other than diamond, there are no substances that exceed these performances. When cutting ferrous materials by PCD, chemical reaction occurs and graphitization progresses. However, this is not the case with PcBN.

It has the advantage that almost no chemical reaction occurs even when it is used for iron, nickel, cobalt, etc. Furthermore, no oxidation occurs even at high temperature of 1,200 ℃.

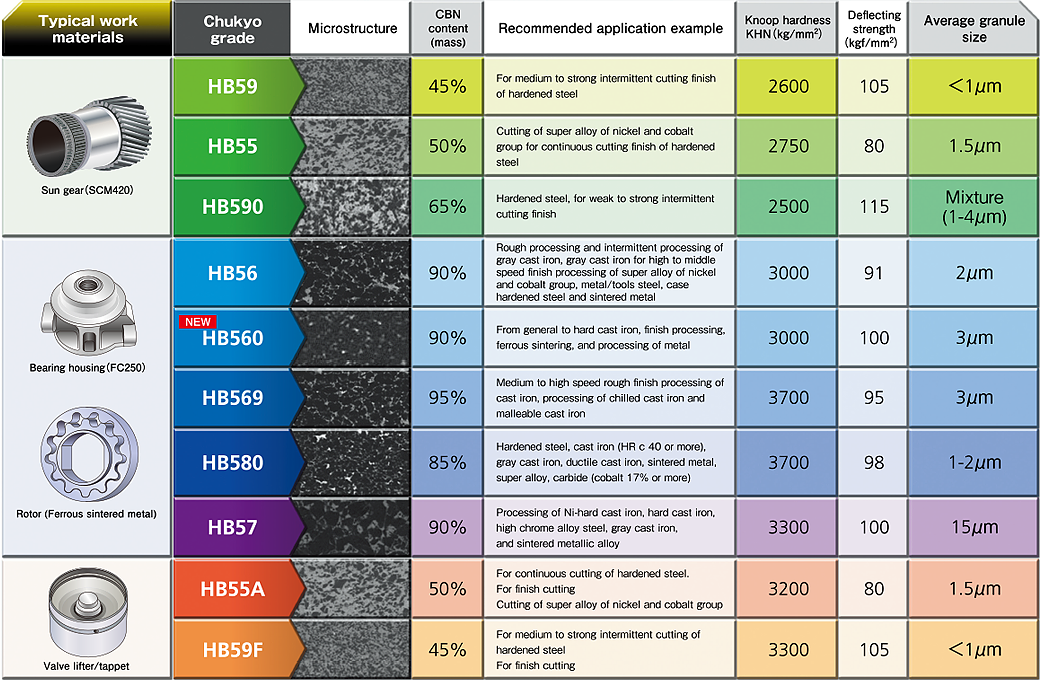

Chukyo PcBN grade table

|

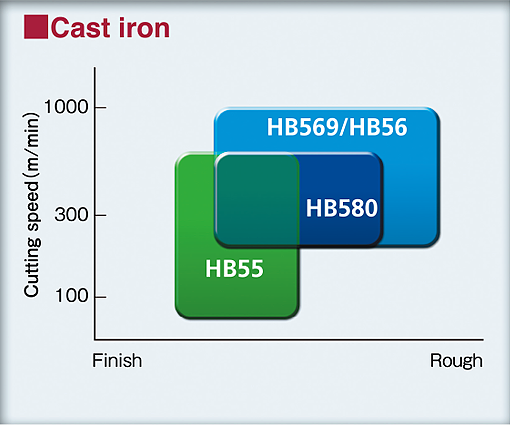

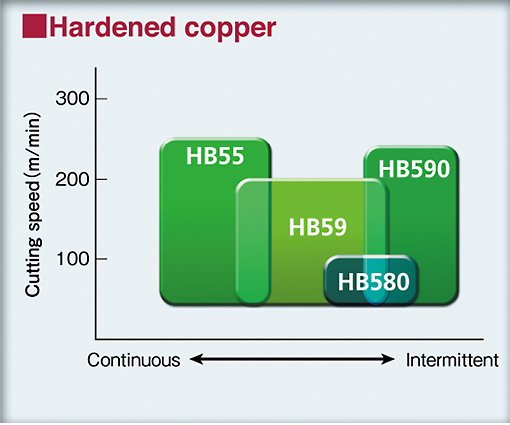

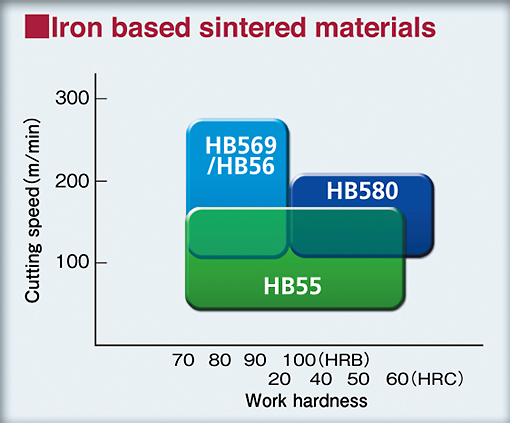

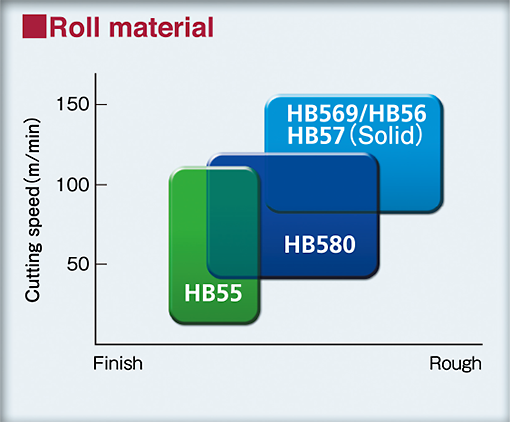

HB series processing area

|

|

|

|

|

|

List of products

List of products PcBN insert

PcBN insert